Best Stainless Steel Woven Wire Mesh Options for Your Needs?

When choosing the best stainless steel woven wire mesh, it’s essential to understand your specific needs. This material offers remarkable durability and corrosion resistance. Many industries rely on it for filtration, security, and reinforcement.

stainless steel woven wire mesh is versatile. It comes in various sizes and styles, suitable for different applications. You might find it overwhelming to decide which option suits you best. Consider the mesh opening size that matches your project. A fine mesh serves well in filtering, while a larger opening can provide better airflow.

It’s wise to evaluate quality and price as you shop. Opting for the cheapest options might lead to issues later. Sometimes, higher quality mesh is worth the investment. Reflect on how each choice impacts your final outcome. Selecting the right stainless steel woven wire mesh is crucial for your success.

Understanding Stainless Steel Woven Wire Mesh Types and Properties

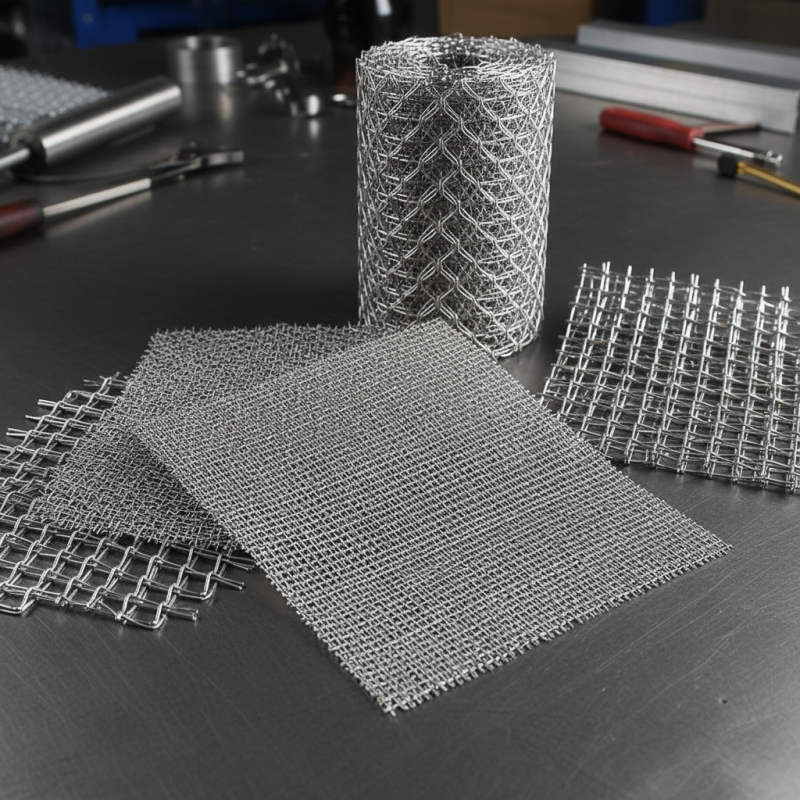

Stainless steel woven wire mesh is versatile and durable. It comes in various types, each with unique properties. The main types include plain weave, twill weave, and Dutch weave. Plain weave is simple and strong, making it suitable for most applications. Twill weave has a diagonal pattern, providing extra strength and flexibility. Dutch weave, often used for filtration, offers fine openings and high tensile strength.

Understanding the properties of these meshes is crucial. Corrosion resistance is a significant advantage of stainless steel. It withstands harsh environments without degrading. The mesh's size and wire thickness impact its strength and filtering capabilities. This means selecting the right option can be challenging. Sometimes, users choose the wrong mesh due to unclear specifications.

Moreover, the aesthetic appeal of stainless steel woven wire mesh cannot be overlooked. It fits well in modern architecture and design projects. However, some find it costly compared to other materials. Budget constraints may lead to inadequate choices. Balancing cost, durability, and functionality is essential. Users should reflect on their specific needs before making a decision.

Key Factors to Consider When Choosing Stainless Steel Mesh

When selecting stainless steel woven wire mesh, several key factors are crucial. Material grade is at the forefront. Common grades like 304 and 316 offer different corrosion resistance. The right choice depends on your specific environment. For instance, Grade 316 is ideal for marine applications due to its superior resistance to saltwater.

Mesh size and wire diameter also play pivotal roles. The mesh opening affects filtration efficiency. Smaller openings can capture fine particles effectively, while larger openings allow for greater airflow. Statistical data suggests that using a 0.5 mm wire diameter increases tensile strength by about 30%. This contributes to durability but may alter your application.

Lastly, consider the intended application. Different industries have varying requirements. For instance, in food processing, it is essential to have a mesh that meets health standards. This often means selecting a mesh that is easy to clean and resistant to various chemicals. It's also important to reflect on whether the chosen mesh meets long-term operational needs. Many overlook potential wear and tear, only to face replacements sooner than expected.

Common Applications for Stainless Steel Woven Wire Mesh

Stainless steel woven wire mesh serves various practical applications across multiple industries. Its durability and corrosion resistance make it a popular choice for filtration and separation processes. In food processing, it ensures purity by preventing contaminants from entering products. The mesh is strong yet flexible, ideal for straining liquids or consolidating dry ingredients.

In construction, stainless steel woven wire mesh is often used for safety barriers and support structures. Its resilience to harsh environments makes it an effective solution for outdoor applications. However, while it holds up well, some may find that it requires regular maintenance to avoid rust over time. It’s crucial to consider the specific environment where the mesh will be used.

Another common application is in the automotive industry. Here, it serves as protective screens in machinery. The mesh allows for airflow while keeping debris out. However, it may not always provide the same rigidity as other materials, leading to potential limitations in certain uses. Analyzing these factors can help in making informed decisions about the best options for your needs.

Best Stainless Steel Woven Wire Mesh Options for Your Needs

| Mesh Type | Wire Diameter (mm) | Aperture Size (mm) | Weave Pattern | Common Applications |

|---|---|---|---|---|

| Plain Woven Mesh | 0.5 - 3.0 | 0.2 - 20.0 | Plain | Filtration, sieving |

| Dutch Woven Mesh | 0.2 - 2.0 | 0.1 - 5.0 | Dutch | Pharmaceutical, food processing |

| Twill Woven Mesh | 0.3 - 3.5 | 0.5 - 15.0 | Twill | Mining, chemical industries |

| Square Woven Mesh | 0.5 - 4.0 | 1.0 - 25.0 | Square | Construction, fencing |

| Hexagonal Woven Mesh | 0.5 - 2.0 | 10.0 - 50.0 | Hexagonal | Chicken coops, garden fences |

Comparative Analysis of Different Stainless Steel Grades

When considering stainless steel woven wire mesh, it's crucial to analyze the different grades available. Stainless steel grades like 304 and 316 are common choices but have distinct properties. Grade 304 is known for its excellent corrosion resistance and versatility. It is widely used in food processing and architectural applications. However, it may not perform as well in highly saline environments.

On the other hand, grade 316 offers superior corrosion resistance, particularly against chlorides. This makes it perfect for marine applications. A report by the American Iron and Steel Institute states that 316 stainless steel can withstand harsh conditions more effectively than 304. However, 316 can also be more expensive, posing a budgetary concern for some projects.

It's essential to evaluate your specific needs before choosing a grade. While 304 may suffice in a dry environment, 316 is necessary for coastal areas. Not all projects require premium materials. Assessing application requirements will ensure you choose the right mesh type. Sometimes, opting for a less expensive grade can lead to future maintenance issues. Balancing cost against performance is a continuing challenge in material selection.

Maintenance Tips for Long-lasting Stainless Steel Wire Mesh Solutions

Stainless steel woven wire mesh is favored for its strength and durability. Regular maintenance ensures that it lasts longer. Cleaning is essential to remove dirt and corrosion. A report from the Stainless Steel Institute states that 70% of stainless steel failures are due to improper care. To prevent this, a simple routine can make a difference.

Using a mild detergent mixed with water works well. Scrub gently with a soft brush. Avoid abrasive cleaners, as they can damage the surface. Afterward, rinse thoroughly to eliminate any residue. It’s crucial to dry the mesh to avoid water spots. Even minor neglect can lead to rust, which is a common issue.

Inspecting the mesh regularly is advisable. Look for any signs of wear or damage. Early detection can save costs on replacements. Over time, environmental factors like humidity can affect its integrity. Keeping the mesh in a sheltered location is wise. This compromises its longevity. Paying attention to these details will ensure your stainless steel wire mesh remains effective for years.