How to Find the Best Mechanical Parts Suppliers for Your Needs?

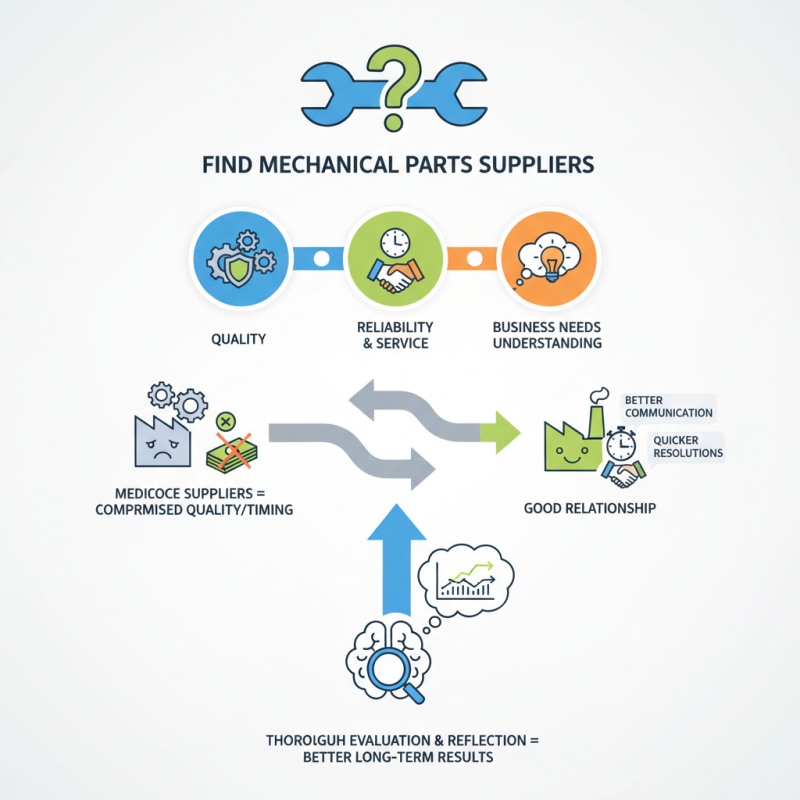

Finding the right mechanical parts suppliers can significantly impact your operations. According to John Smith, an expert in supply chain management, “Choosing the right supplier is as crucial as the parts themselves.” Selecting a supplier involves assessing quality, reliability, and service.

Many companies face challenges when sifting through numerous options. It’s not merely about price or proximity. Having a supplier who understands your business needs is essential. A good relationship can lead to better communication and quicker resolutions.

Sometimes, businesses settle for mediocre suppliers. They may overlook critical factors that compromise quality or timing. Taking the time to evaluate suppliers thoroughly will yield better long-term results. Reflecting on past decisions can guide your future choices in mechanical parts suppliers.

Identify Your Specific Mechanical Parts Requirements

Identifying your specific mechanical parts requirements is crucial for effective procurement. Begin by assessing your project needs. Consider the materials, dimensions, and tolerances necessary for your application. Create a clear list of specifications that includes every detail. This will serve as your guiding document during the selection process.

Next, think about the environment where these parts will operate. Will they face extreme temperatures or corrosive substances? This information will narrow down your supplier choices. Engaging with engineers or design teams can provide valuable insights. They may highlight aspects you overlooked. Communication is key.

It's also worthwhile to reflect on past experiences. Have there been issues with reliability or delivery times? Document these challenges. This record can help refine your criteria. Searching for a supplier isn’t just about price. Quality and support matter too. A good partnership can lead to improved project outcomes.

Research Potential Suppliers in the Market

When searching for mechanical parts suppliers, thorough research is crucial. A recent industry report from the Manufacturers' Association indicates that nearly 60% of companies fail to evaluate supplier capabilities properly. This oversight often leads to mismatched quality expectations and supply delays. Understanding the market landscape can provide valuable insights into potential candidates.

Consider examining supplier certifications and industry reputation. According to the 2022 Supply Chain Insights study, 70% of successful projects resulted from suppliers with established quality management systems. Seek references and reviews from previous customers. Verified feedback can illuminate potential risks. Additionally, pay attention to factors such as delivery times and pricing structures, as they are often indicators of overall reliability.

Market trends also reveal the importance of localization. The same industry report noted that suppliers located closer to manufacturing operations often demonstrate better responsiveness. This can enhance communication and reduce lead times. However, some businesses may overlook local options in favor of lower-cost alternatives abroad, which can lead to unexpected complications. Always weigh the pros and cons of sourcing decisions.

Evaluate Supplier Credentials and Reputation

When choosing mechanical parts suppliers, evaluating their credentials is crucial. A recent survey by the Institute for Supply Management revealed that 71% of companies faced supply chain disruptions due to unreliable suppliers. This statistic highlights the necessity of sourcing from reputable providers. Suppliers should have certifications like ISO 9001. These credentials indicate a commitment to quality management systems.

Research indicates that companies that vet supplier reputations see a 25% reduction in defects. Online reviews and industry references can provide insights into supplier reliability. However, not all feedback is favorable. Some might be inflated or misleading. It is essential to look for patterns in reviews over time. One positive review from a few years ago does not ensure consistent service.

Many suppliers may offer attractive pricing, but costs should not be the only factor. Compromising on quality can lead to long-term expenses. A study from Machinery and Equipment reported that 30% of firms experienced increased costs due to poor supplier choice. It’s vital to balance cost and quality. Seeking suppliers with a proven track record is key to maintaining operational efficiency.

Supplier Comparison for Mechanical Parts

Assess Quality Control and Manufacturing Standards

Quality control is crucial when selecting mechanical parts suppliers. The manufacturing standards they adhere to directly impact product reliability. According to a 2022 report from the International Organization for Standardization, companies with robust quality management systems saw a 25% reduction in defects. This statistic underscores the importance of evaluating suppliers' quality control processes.

Inspect the supplier's certifications. Are they ISO 9001 certified? This standard ensures that a company consistently meets customer requirements. Additionally, consider their inspection protocols. A supplier should not only perform routine checks but also document them thoroughly. This transparency can highlight their commitment to quality.

Look for customer feedback on supplier performance. A survey in 2023 noted that 48% of customers reported issues related to poor quality from suppliers lacking stringent quality controls. This data suggests that skipping a detailed assessment can lead to costly complications. Reflect on previous experiences where a lack of quality assurance resulted in delays or increased costs. Prioritizing quality will save time and resources in the long run.

How to Find the Best Mechanical Parts Suppliers for Your Needs?

| Supplier Location | Manufacturing Standards | Quality Control Certification | Lead Time (Days) | Minimum Order Quantity |

|---|---|---|---|---|

| USA | ISO 9001 | ISO 13485 | 15 | 100 |

| Germany | DIN EN ISO 9001 | TÜV | 20 | 50 |

| China | ISO 9001 | SGS | 30 | 200 |

| Japan | JIS Q 9001 | AISO | 10 | 75 |

| India | ISO 9001 | BIS | 25 | 150 |

Obtain Quotes and Compare Pricing and Terms

When searching for mechanical parts suppliers, obtaining quotes is essential. It’s important to reach out to multiple suppliers. This helps to compare pricing and terms effectively. You can ask for specific items you need. Include detailed descriptions. This can help suppliers provide accurate quotes.

Once you receive the quotes, take time to compare them. Look beyond just the price. Assess the delivery times and payment terms. Some suppliers may offer faster shipping. Others might have better payment flexibility. This can impact your overall cost. Don't forget to read terms carefully. Hidden fees can significantly alter the deal.

Consider the quality of the products too. Sometimes lower prices reflect lower quality. It’s essential to balance cost and quality. Engage with suppliers to ask questions. This helps clarify any doubts. A strong relationship can lead to better terms in the future.

Reflect on your choices throughout the process. What worked well? What needs improvement? Taking these steps ensures you find the best supplier for your mechanical parts needs.