What is an airport fence and why is it important?

An airport fence is more than just a physical barrier. It stands as a crucial line of defense for airport security. These fences are designed to prevent unauthorized access to sensitive areas. They help protect passengers, staff, and aircraft. The materials used in constructing an airport fence can vary, but durability is key.

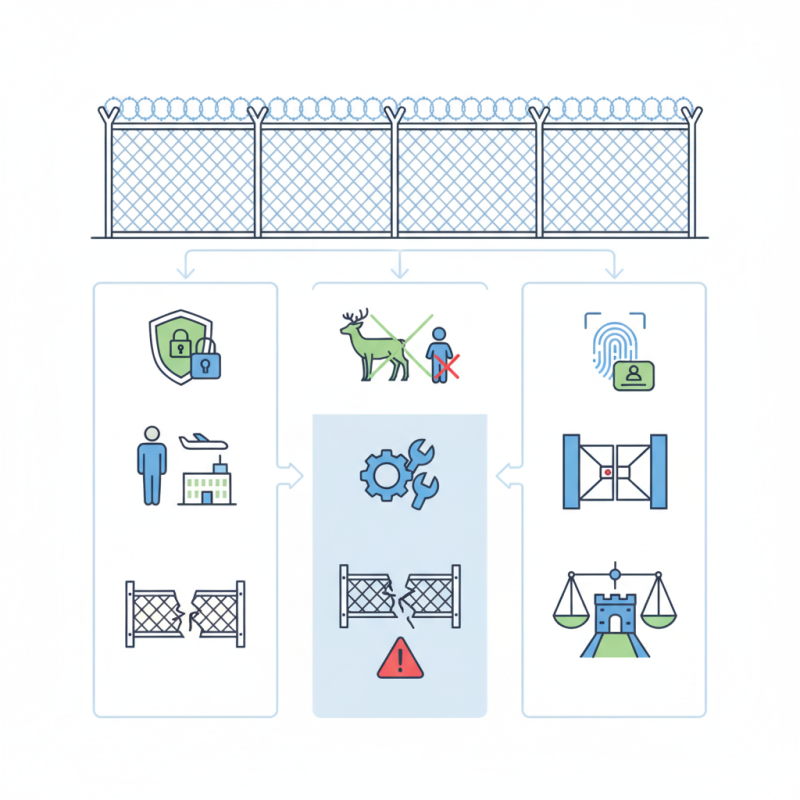

A well-designed airport fence enhances safety. It deters intruders and can discourage dangerous wildlife from entering the runway. However, maintaining these fences is often overlooked. Some airports may find gaps or weaknesses in their fencing. This raises concerns about potential breaches. The importance of regular inspections and repairs cannot be underestimated.

The airport fence plays a role in accessibility as well. While it secures the area, it must also allow authorized personnel easy entry. Finding a balance can be tricky. A secure yet accessible fence is ideal but not always achieved. Airports must continuously assess their fencing strategies to improve security while accommodating necessary access.

What is an Airport Fence?

An airport fence is a critical security measure. It serves as a physical barrier, protecting the airport's perimeter. According to the Airport Cooperative Research Program, a robust fence can reduce unauthorized access by up to 70%. This statistic illustrates the importance of effective fencing systems.

Airport fences can take many forms. Chain-link fences are common but may not offer the highest security. Some airports opt for electrified fences or those with barbed wire. Each option has its pros and cons. In recent years, a surge in airport security threats has led to more advanced fence technologies. The Transportation Security Administration recommends using secure fencing alongside surveillance cameras.

However, not all airports have implemented these measures. Many facilities still rely on outdated security systems. The International Air Transport Association reports that 20% of airports lack adequate perimeter security. This gap raises concerns. As threats evolve, a rethink of airport fencing is necessary. The balance between cost and security remains a dilemma. Airports must assess their unique risks and plan accordingly.

Functions of an Airport Fence in Security Systems

An airport fence serves as a crucial line of defense in security systems. This physical barrier prevents unauthorized access to sensitive areas. Without it, the risks of breaches increase significantly. Airport fences are often tall and robust, designed to deter intruders. They are equipped with barbed wire or electric components for added protection.

In addition to blocking intruders, airport fences delineate safe zones. They guide traffic patterns and control movement. This organization is essential to maintain security. Cameras and motion detectors are frequently integrated into the fence. These technologies enhance surveillance capabilities. They help in monitoring for suspicious activities.

However, relying solely on fences can be flawed. They do not guarantee complete security. Breaches can still occur, especially in poorly monitored sections. Regular inspections and maintenance are necessary to ensure effectiveness. Each airport must adapt its security measures continuously. Balancing human oversight and technology is vital for a robust security system. Good practices must be developed and refined over time.

Types of Airport Fences and Their Specifications

Airport fences are crucial for security and safety. They serve as the first line of defense against unauthorized access. Various types of fences are used, each with specific requirements. Chain-link fences are common due to their cost-effectiveness. They typically reach heights of 8 to 10 feet. Their visibility still allows monitoring by security staff.

Another type is electrified fencing. This offers heightened security with a deterrent effect. Electrified fences can be an effective barrier, making unauthorized entry dangerous. A report by the Transportation Security Administration indicates that over 90% of U.S. airports use a combination of fencing types. This layered approach enhances protection against intrusions and wildlife threats.

Welded wire fences are also popular. They provide higher strength and durability. These fences can withstand harsh environmental conditions. However, they may require more maintenance over time. The choice of fencing material can influence overall airport security strategy. Each option has strengths and weaknesses, requiring thoughtful consideration.

Regulatory Standards Governing Airport Fencing

Airport fencing serves a crucial role in maintaining security. Various regulations govern the design and construction of these fences. According to the Federal Aviation Administration (FAA), fencing must meet specific height and security standards. Typically, airport fences must be at least eight feet high and made of robust materials to deter breaches.

The Transportation Security Administration (TSA) outlines additional requirements. They emphasize the importance of visibility. Fences should be clear of obstructions, ensuring guard patrols can monitor them effectively. A study by the National Institute of Standards and Technology (NIST) found that nearly 20% of airport breaches occurred due to inadequate fencing. Such statistics highlight the need for strict adherence to regulations.

However, there can be shortcomings in implementation. Some airports may opt for cost-saving measures. This can lead to the use of substandard materials or overlooked maintenance. A well-designed airport fence should not only deter unauthorized access but also provide a clear boundary. Reflecting on these challenges can lead to improved standards in airport security.

What is an airport fence and why is it important? - Regulatory Standards Governing Airport Fencing

| Dimension | Specification | Importance |

|---|---|---|

| Height | 8 feet (2.44 meters) | Prevents unauthorized access from ground level. |

| Material | Chain-link with barbed wire top | Durable and acts as a deterrent against intrusions. |

| Length | Varies depending on airport size | Defines perimeter and secures the area around the airport. |

| Gate Access | Controlled entry points | Allows secure entry for authorized personnel only. |

| Signage | Warning and no trespassing signs | Informs individuals of legal boundaries and security measures. |

| Lighting | Adequate perimeter lighting | Enhances visibility and security at night. |

Impact of Airport Fences on Safety and Wildlife Conservation

Airport fences serve a dual purpose: ensuring safety and aiding wildlife conservation. These structures are designed to prevent unauthorized access to runways while protecting various animal species. A well-constructed fence stops animals from entering active flight zones, thus minimizing accidents. Birds and other wildlife may inadvertently cause catastrophic events if they encounter aircraft.

Effective airport fencing should be sturdy yet considerate of local wildlife. For instance, using wildlife-friendly materials can help prevent animal entrapment. The design can include gaps and natural barriers that allow smaller animals to pass while deterring larger ones. This approach helps preserve local ecosystems. It’s essential to balance aviation safety and wildlife protection.

**Tips**:

- Regular inspections ensure the fence is intact.

- Keeping the area clear of debris can reduce animal attraction.

- Collaborate with wildlife experts for better designs.

While fences are vital, they need continuous evaluation. Maintenance is often overlooked yet crucial. Fences should adapt to changing wildlife patterns. Engaging with the community is also important. Inputs from local residents can lead to innovative solutions that benefit both safety and wildlife conservation.